Our Soot Blower Family

Our soot blowers are entirely “Made in Germany”

The System:

The design of our soot blower family is based on over 20 years of practical experience in soot blower service and optimization.

The soot blowers have been designed for the toughest operating conditions in plants with challenging fuels, such as waste incineration plants and biomass power plants. Depending on the cleaning task and availability, steam, compressed air, or water are used as cleaning media.

Our soot blowers are entirely “Made in Germany” and are exclusively manufactured at our factory in Salzgitter. This ensures, as with our other cleaning systems, the highest quality and shortest delivery times.

Advantages of our soot blower systems:

• Robust, power plant-ready construction

• Modular design of the different types of soot blowers. This reduces the need for spare parts inventory.

• Cast valve for long service life

• Standard with blast jet offset to protect the heating surfaces

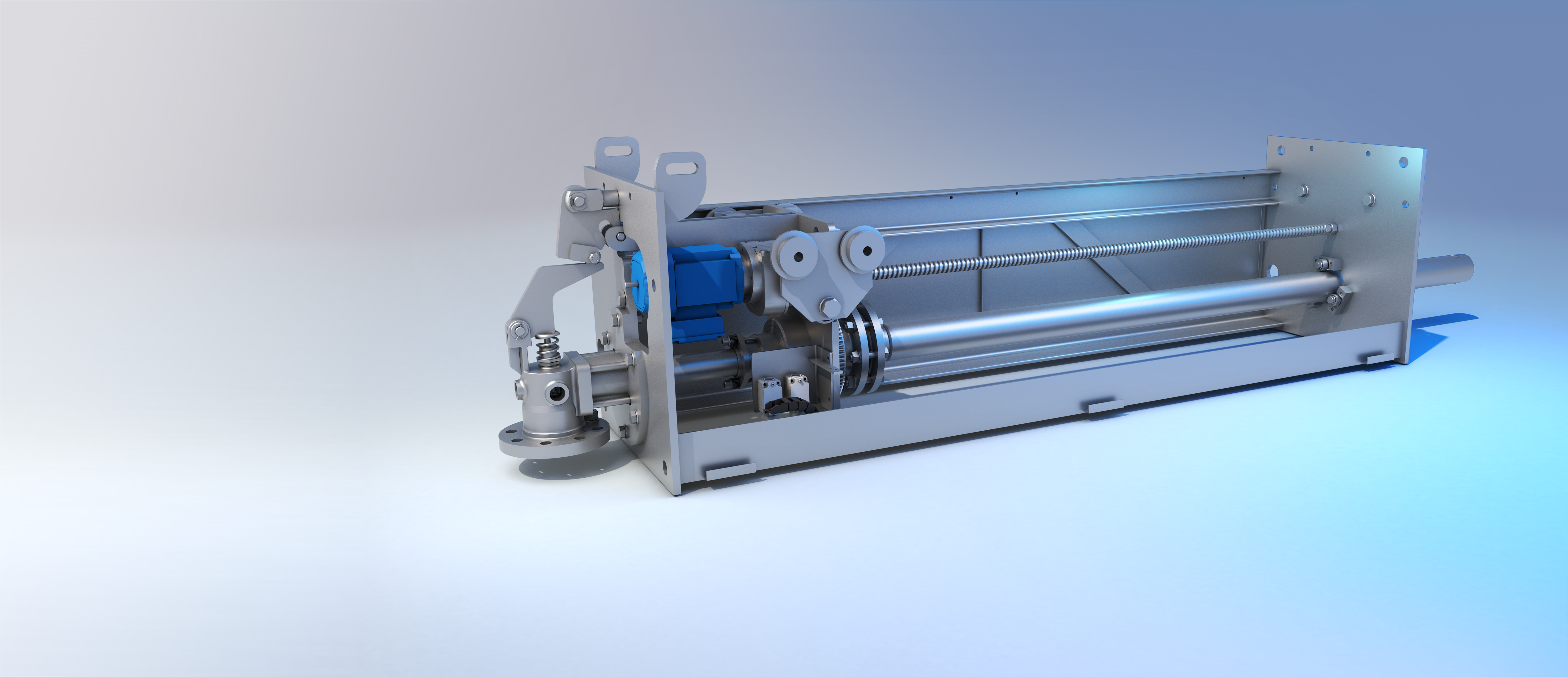

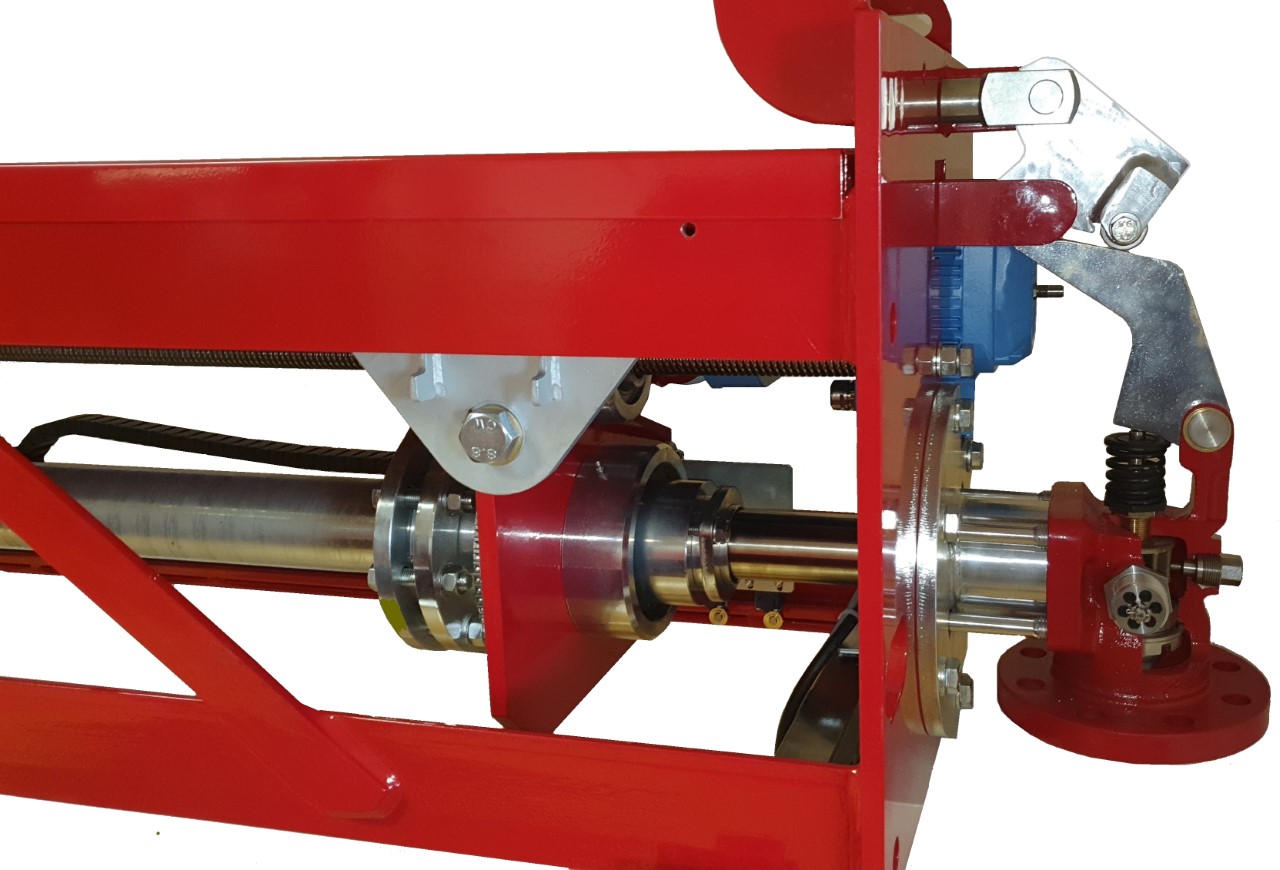

Lance Screw Blower LSB22

The lance screw blower is based on the principle that a lance tube with two opposing high-performance nozzles is spirally moved into the flue gas path. The lance tube completely exits the flue gas path and is therefore suitable for temperatures up to 1000°C.

Data for LSB22:

- Type: Lance Screw Blower

- Range: Up to approximately 1000°C flue gas temperature

- Travel distance: Up to 10m

- Feature: Lance tube completely exits the boiler

Screw Blower SB22

The screw blower is best suited for areas with flue gas temperatures of up to 450°C (700°C for non-corrosive flue gases). The blow tube of the screw blower remains partially in the flue gas path and is stored there. This results in the advantage of a shorter removal length with typically 4 high-performance nozzles. The SB22 is used for travel distances of up to 6 meters.

Data for SB22:

- Type: Screw Blower

- Range: Up to approximately 450°C flue gas temperature (700°C for non-corrosive flue gases)

- Travel distance: Up to 6m

- Feature: Shorter removal length, blow tube remains partially in the boiler

Pendulum Blower PB22

The pendulum blower is designed for the first or last heating surface in a flue gas path and therefore cleans only in one direction. In the pendulum blower PB22, the blast jet of the high-performance nozzle oscillates over the heating surface during axial movement. It is largely identical to the robust LSB22 or SB22 and is available in both fully and partially retractable versions.

- Type: Pendulum Blower

- Range: Up to approximately 1000°C or 450°C flue gas temperature

- Travel distance: Up to 10 or 6m

- Feature: Intensive cleaning through pendulum movement

Traverse Blower TB22

The traverse blower is designed for cleaning economizers and catalysts (SCR systems) at flue gas temperatures of up to approximately 500°C. An axially movable traverse with special high-performance nozzles allows the economizer or catalyst to be cleaned particularly effectively.

- Type: Traverse Blower

- Range: Up to approximately 500°C flue gas temperature

- Travel distance: Up to 6m, pure axial movement

- Feature: One to three traverses (cross arms) with high-performance nozzles

DB22

The rotary blower DB22 is designed for cleaning heating surfaces and heat exchangers with lighter contamination and flue gas temperatures up to 500°C. The blow tube remains completely in the flue gas path and is equipped with nozzles along its entire length. The blow tube of the rotary blower DB22 rotates in the flue gas path without axial movement.

- Type: Rotary Blower

- Range: Up to approximately 500°C flue gas temperature

- Travel distance: No axial movement, 360° rotational movement

- Feature: Minimal removal length, blow tube remains completely in the boiler